Phlux to explain the technology behind high sensitivity, fast recovery avalanche photodiodes at SPIE Defense + Commercial Sensing event

Sheffield, UK, 12th April 2024: Xiao Collins, co-founder and director of Phlux Technology, a manufacturer of avalanche photodiode (APD) infrared sensors, will present a paper at the SPIE Defense + Commercial Sensing show that explains how Phux’s patented AlGaAsSb avalanche photodiodes (APDs) achieve an order of magnitude greater sensitivity than traditional InGaAs devices and exhibit exceptionally fast recovery times.

APDs can provide high sensitivity in applications such as laser range finders, LiDAR, and optical time domain reflectometry working at 1550 nm. This is enhanced when the APDs are fabricated in an AlGaAsSb process. Such devices allow operation at high gain without sacrificing noise performance through a high level of dark current or excess noise.

The presentation by Xiao will be held at National Harbor 12 at 11:15 am on Tuesday 23rd April and commenting on the problems solved by Phlux’s ‘Noiseless InGaAs’ technology, he said:

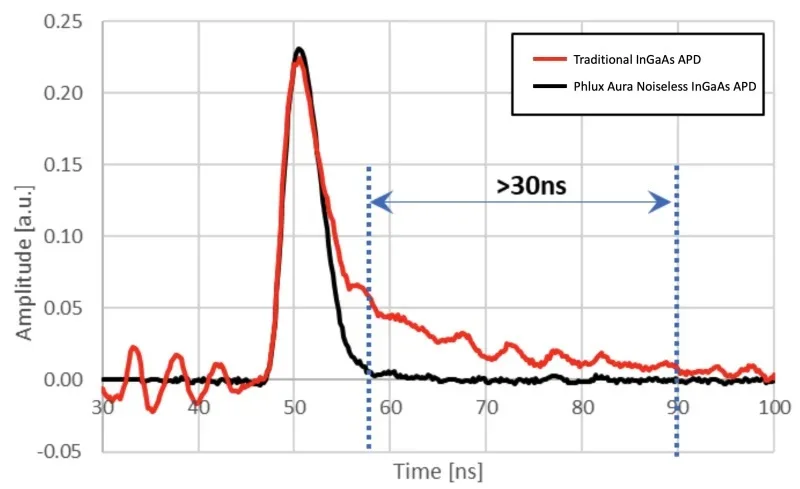

“Traditional InGaAs APD receiver systems can easily be overloaded by high optical input powers causing them to be ‘blind’ to secondary optical signals until they can recover from the first. In this presentation of our study, we report the capability of the Phlux AlGaAsSb APD and transimpedance amplifier (TIA) combination, which not only achieves high sensitivity due to the enhanced APD operating gain but also recovers quickly when illuminated by a high optical power pulse. Finally, we also report on the high damage threshold of the APDs and the failure mechanisms that are found within the components."

Launched in January 2024, Phlux’s Aura Noiseless InGaAsTM 1550 nm APDs are 12X more sensitive than similar best-in-class components. As a result, the operating range of 1550 nm IR systems can be extended by up to 50% by just replacing the APD sensor. Alternatively, the power of the laser diode that generates the signal can be greatly reduced. This simplifies system optics and thermal management, cutting product size and cost.