What is dark current in IR sensors?

Dark current is a critical factor impacting the performance of infrared sensors. It refers to the electrical current that flows through an IR sensor even in complete darkness, arising from internal physical processes rather than incident light. Understanding the causes and consequences of dark current important for the design of advanced IR sensing systems.

Causes of dark current

At the heart of every IR sensor is a semiconductor junction. Even when no photons are present, thermal energy can excite electrons and create charge carriers that drift across this junction, forming a current. This is primarily due to thermal generation - random vibrations and energy within the lattice freeing electrons and holes, which are then swept by the sensor’s electric field.

Imperfections within the crystal structure and at surfaces, such as impurities, defects, or poorly passivated interfaces, also contribute to dark current. These sites can create unwanted paths for charge carriers to recombine or tunnel across the bandgap, elevating the current. In some device architectures, additional mechanisms like generation-recombination in the depletion zone and quantum tunnelling processes become significant, particularly at higher bias voltages or in low-temperature operation.

Dark current influence on sensor performance

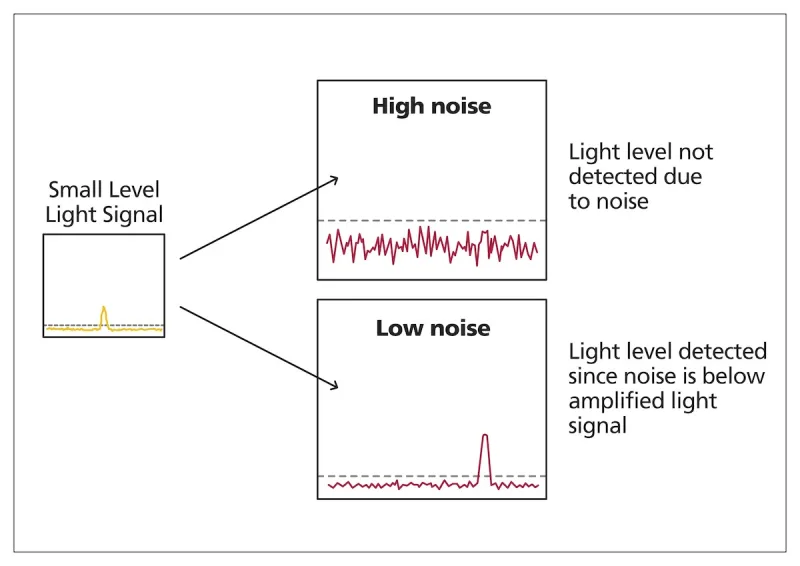

Dark current sets a fundamental limit on the sensitivity of IR sensors. Because it flows independently of any incident light, dark current acts like a background noise, directly decreasing the sensor’s signal-to-noise ratio. For applications requiring detection of extremely faint signals, such as scientific imaging, telecommunications, or LiDAR, high dark current limits the lowest detectable light level and forces shorter integration times, which can reduce both the resolution and range of systems.

It is also highly temperature-dependent, typically doubling for every 7°C to10°C rise. This means colder operation or careful device engineering is often needed for instruments needing high accuracy. High dark current can lead to increased power requirements for laser diode signal sources and necessitate additional circuit complexity and cooling, affecting system size and cost.

Efforts to suppress dark current focus on improving material purity, optimising device structure, adding surface passivation, and other techniques to minimise defect-related conduction or recombination.

Example: Phlux Technology’s low dark current APD

Phlux Technology has set new benchmarks for low dark current IR sensors with the Aura family of Noiseless InGaAs® Avalanche Photodiodes (APDs). The resulting Aura 30 µm APD, for example, operates with an excess noise factor below 3.5 at a gain of 100 and delivers sensitivity twelve times higher than conventional InGaAs APDs.

This device boasts remarkably low dark current even when operated at high temperature, offering superior performance for applications such as optical time domain reflectometry, gigabit-speed fibre communications, and long-range LiDAR.

The use of antimony alloy in Phlux’s compound semiconductor APDs suppresses defect-related noise sources, while advanced semiconductor processing ensures exceptional stability up to +85 °C. The result is a sensor capable of detecting the weakest IR signals in demanding environments, and fast impulse response. The Aura Noiseless InGaAs® APD exemplifies how suppressing dark current enables the latest generation of infrared systems to achieve greater sensitivity, longer range, and lower cost. A more detailed explanation of Phlux’s APD technology can be found here.